RIGID MAX INSTALLATION INSTRUCTIONS

General Information

Each individual plank must be inspected to ensure there are NO surface imperfections or defects. The installer takes full responsibility that each plank is defect free and assumes liability once installed. Materials with visible defects are not covered under warranty once they are installed. Floors that are not installed in accordance to industry standards or instructions below will not be covered under warranty.

The locking installation system allows the planks to be installed without using adhesives. It is a floating floor installation. Do not install fixed objects, such as cabinets, on top of the flooring or fasten trim/molding/transition pieces directly to the floor (unless stair nosing). The planks should be installed 1/4˝ away from all vertical surfaces such as walls, cabinets, pipes, etc.

Product Inspections

- Inspection of all subfloor, jobsite conditions and flooring material must be done prior to the installation.

- Materials with visible defects are not covered under warranties once they are installed.

- Rigid Max floors are manufactured in accordance with accepted industry standards.

Sub-Floor Preparation

- Sub-floor must be flat, dry, smooth, level, free from residues and structurally sound.

- A level foundation that is less from 3/16” over a 10 foot diameter span.

- Irregularities in concrete, embossed existing resilient floors, ceramic tile floors, ceramic and marble grout joints, should be filled and leveled using a cementitious based patch.

Site Conditions

- The area to receive Rigid Max flooring should be maintained between 65°F (18°C) and 80°F (29°C) for 48 hours before installation, during installation, and 48 hours after completion.

- Radiant heated substrates must not exceed a maximum surface temperature of 85°F (29°C).

- Remove baseboard, quarter-round moldings, wall base, appliances and furniture from room.

- After preparation work, sweep and vacuum the entire work area to remove all dust and debris.

Installation Guidelines

- Rigid Max flooring must be installed indoors.

- Work out of 4 boxes at a time to create “random” variation.

- Determine which direction the plank will Find the center of each of the end walls (the walls perpendicular to the long dimension of the planks and place a pencil mark on the floor. Many installations will run off the longest wall.

- Door trim should be under-cut to allow flooring to move freely without being pinched.

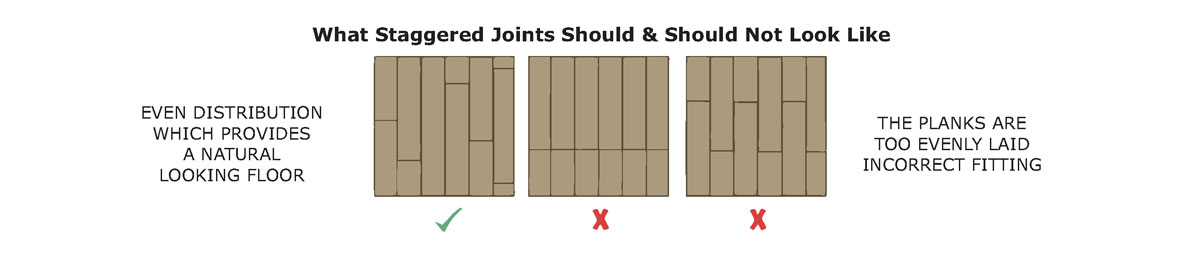

- Whenever possible, plan the layout so that the joints in the planks do not fall on top of joints or seams in the existing substrate. The end joints of the planks should be staggered a minimum of 6˝ apart.

- Do not install pieces shorter than 8˝ in length on any row and 2” in width for starting & finishing rows.

- Do not repeat your cut pattern for less 3+ rows for best random appearance.

INSTALLATION:

Rigid Max flooring must be installed indoors.

Remove the tongue (on the long side) from the first row of planks.

Note: The first row of planks may need to be trimmed lengthwise for a better fit at the end of the installation. Measure the room and divide by the width of the plank. If there is a remainder of less than 2”, the first row will need to be trimmed by that amount.

Starting in the left-hand corner, place the first plank with its trimmed side towards the wall. Use spacers along each wall to maintain an expansion gap of 1/4” (7-8mm) around the parameter.

Attach the ends of the 1st plank and the second plank by lifting the 2nd plank and inserting the tongue on the short side into the groove of the first plank and lowering it into place. Line up edges and corners carefully to make sure they are ALL perfectly aligned.

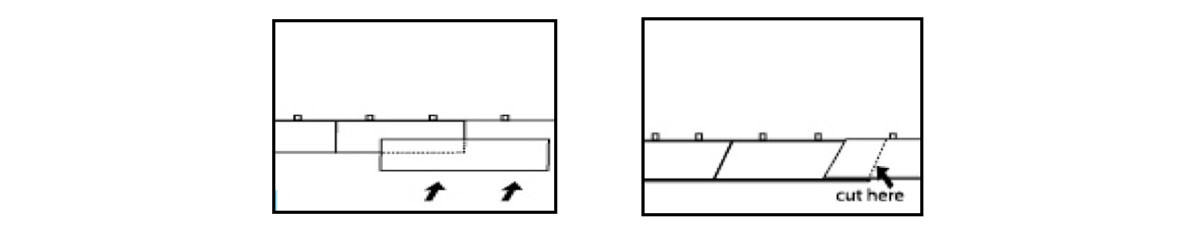

Continue along the wall until you reach the last full plank, connecting each plank in manner described above. To fit the last plank, turn plank over (face down). Place the plank in the corner so the tongue on the short end touches the adjacent wall. Measure overlap between the installed plank and the last plank.

Using a sharp utility knife or shears and a straight edge, score a line on the top surface of the plank. The plank should split on the score line with little effort. Use saw to cut plank to size. Note: the end pieces must be longer than 8”. This may require cutting a plank to start a row depending on the size of the room.

Begin the next row with the cut off piece from the previous row to create the necessary stagger pattern. This piece should be a minimum of 8” (20cm) long and the joint offset from the previous row should be at least 6” (26cm) apart.

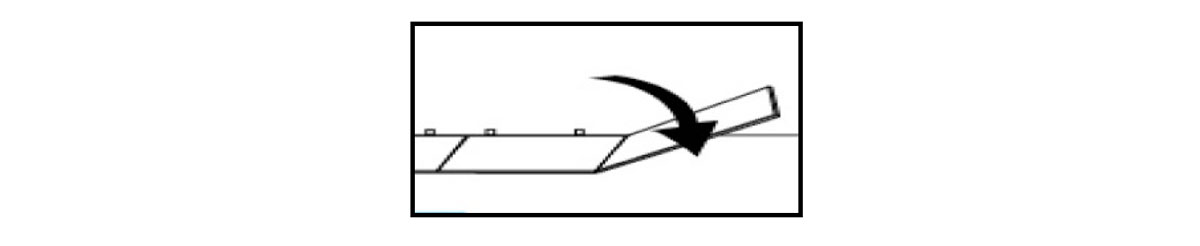

To attach, tilt the plank you are installing slightly upwards (about 15-25º), insert its tongue into the previous row’s groove and lower it into place. The plank will click into place with light pressure.

Install the second plank in the second row by inserting the short end tongue into the previously installed plank’s groove. Align the plank so that the long side tongue tip is positioned just over the groove lip of the plank in the first row. Working from the end seam, at a low angle, insert the long tongue into the groove of the adjoining plank.

Continue the process until reaching the final row of the area.

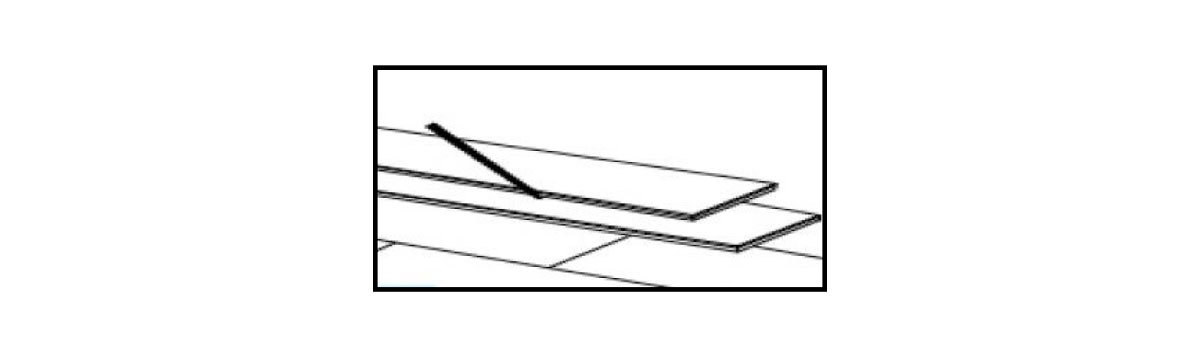

To fit the last row, lay a plank on top of the previous row. With the plank against the wall, mark a line down the length of the plank and cut the planks accordingly.

To finish the perimeter of the room, install quarter round or base molding covering the expansion gap using finishing nails. Nail quarter round or base molding directly into the baseboard not the flooring.

WARRANTY:

Each individual plank must be thoroughly inspected to ensure there are NO surface imperfections or defects. The installer takes full responsibility that each plank is defect free and assumes liability once installed. Materials with visible defects are not covered under warranties once they are installed.

EXCLUSIONS:

- Any visible defects noted after installation.

- Consequential or incidental damages, such as any loss, expense or damages other than to the flooring itself that may result from a defect in the flooring.

- Improper installation.

- Improper maintenance or inadequate care, including, but not limited to, mold or mildew growth as a result of excessive moisture accumulation BELOW the material.

- Accidents, abuse, or misuse. Building settling or uneven sub-floor.

- Damages caused by furniture without felt pads or protective covers. Damages caused by sharp objects making contact with the floor.

- During peak hours of sunlight, blinds, shades or drapes should be closed to lessen the potential impact.

MAINTENANCE INFORMATION:

- Place rugs at entry points to help trap grit and absorb moisture that may damage the finish. This can protect the floors from dirt or wear.

- To prevent abrasive dirt and dust from accumulating and scratching the finish sweep or vacuum without a beater bar daily or as needed. Dry wipe as primary cleaning method. Occasionally damp wipe with water only. NO wet washing.

- If cleaning is needed, use 1/3 cup non-sudsing ammonia per gallon of water OR use 1 cup of vinegar per gallon of water. DO NOT use detergents, abrasive cleaners, soaps, waxes or polishes. Wipe off spills immediately.

- During intense sunlight use window coverings for precautionary measures.

- Do not roll or drag heavy objects across your floor. Do not wear shoes having heel taps, spikes, cleats, rocks, gravel or sharp objects protruding from the sole.

- Add felt pads to all furniture and chair legs to prevent damage to the floor. Replace the felt pads when dirty or worn. For extremely heavy objects, use wide, non-staining rubber cups. Protective floor coverings for wheeled office furniture should be used.